XR FOR EVERY PLANT LIFECYCLE STAGE

Research & Development

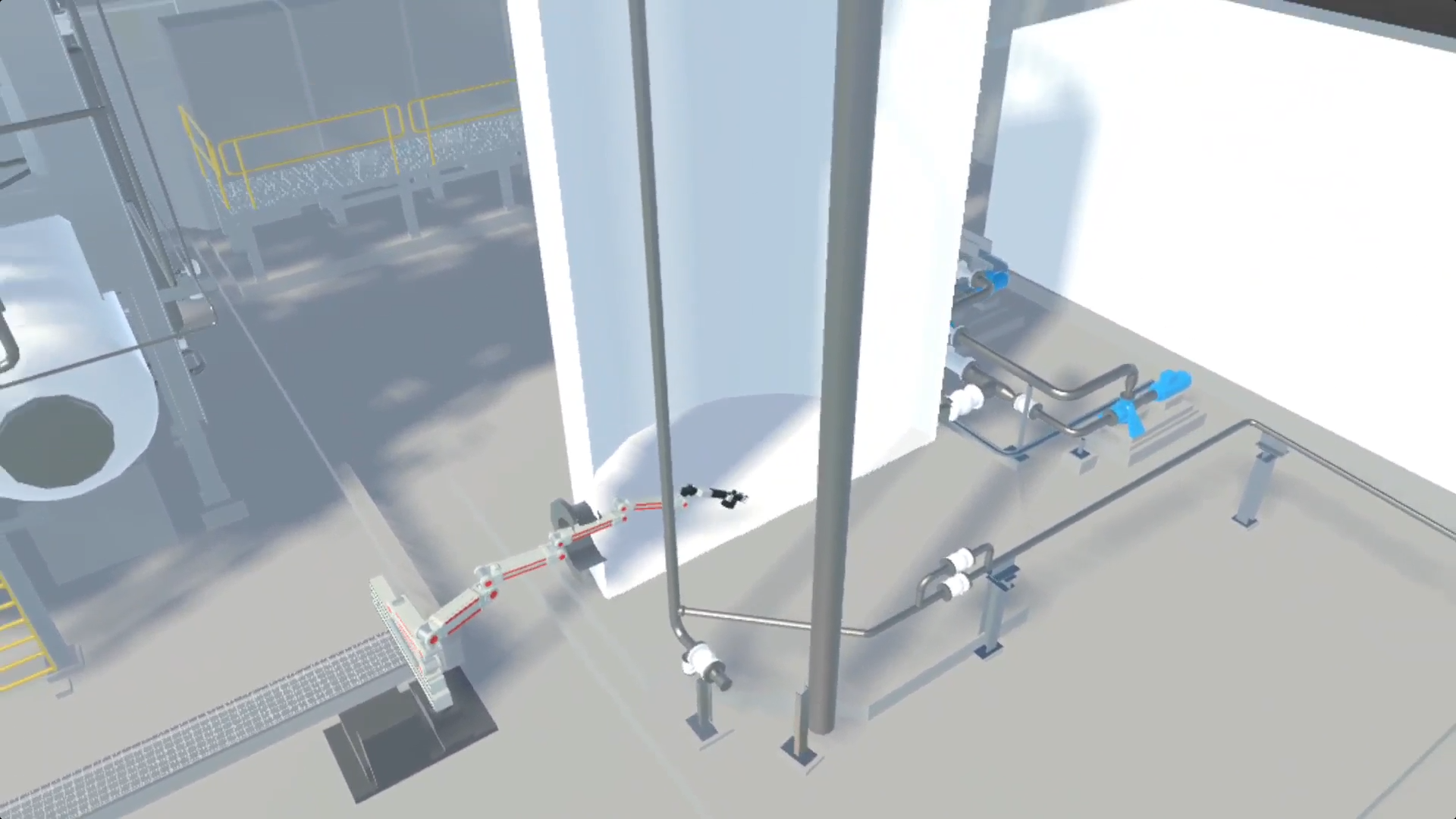

XR use case: Create a pilot plant of your process in XR, simulate and investigate the results in 3D

Problem: A pilot plant is a small-scale industrial facility used to test and optimize processes before full-scale production. These pilot plants are often not co-located with the large-scale facilities and are experimental in nature, making them not easily accessible and requiring frequent adjustments.

Solution: We provide applications to integrate and adapt your pilot plant in XR, with modelling capabilities behind it, allowing you to collaborate on the next generation of products with your pilot crew.

XR FOR EVERY PLANT LIFECYCLE STAGE

Design & Engineering

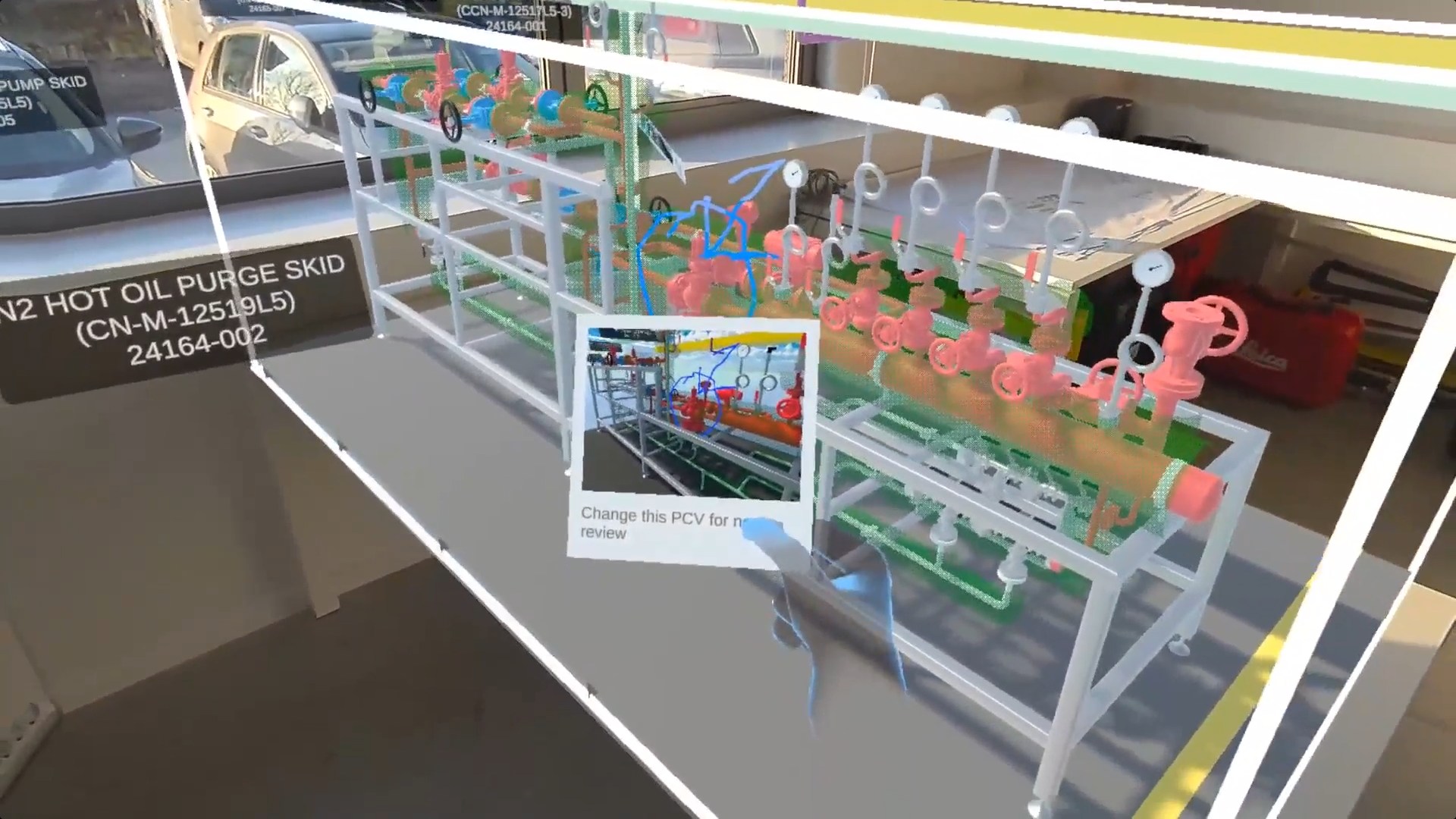

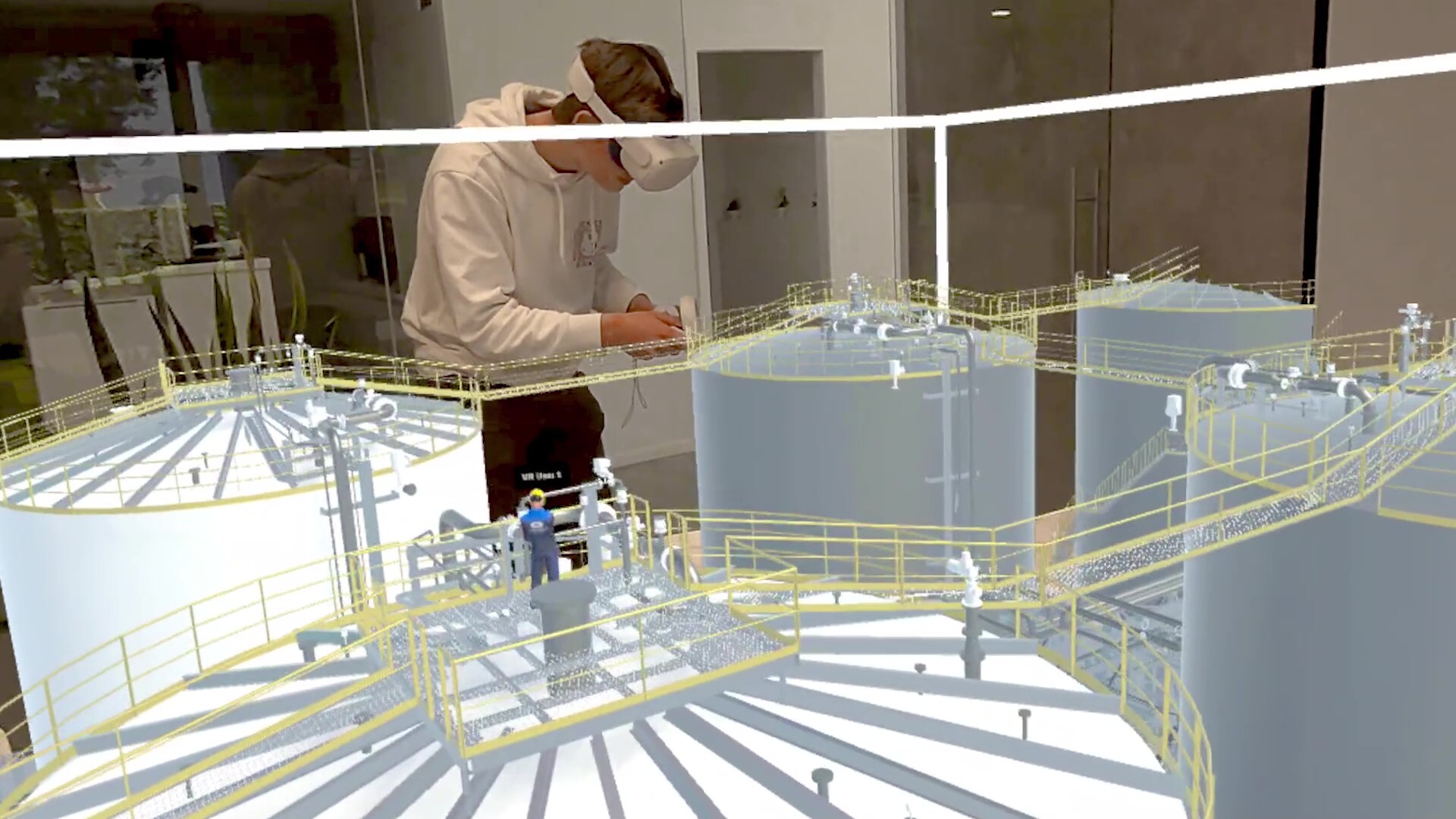

XR use case: Experience design review more effectively with XR

Problem: The design and engineering of a new process plant can be very complex and requires multiple teams to be aligned. Lack of spatial understanding and miscommunications can lead to costly errors and ergonomic inefficiencies identified later in the process.

Solution: With our XR design review tool, errors can be detected early in the process with a personal point of view, while also enabling collaboration from anywhere in an interactive way

XR FOR EVERY PLANT LIFECYCLE STAGE

Construction

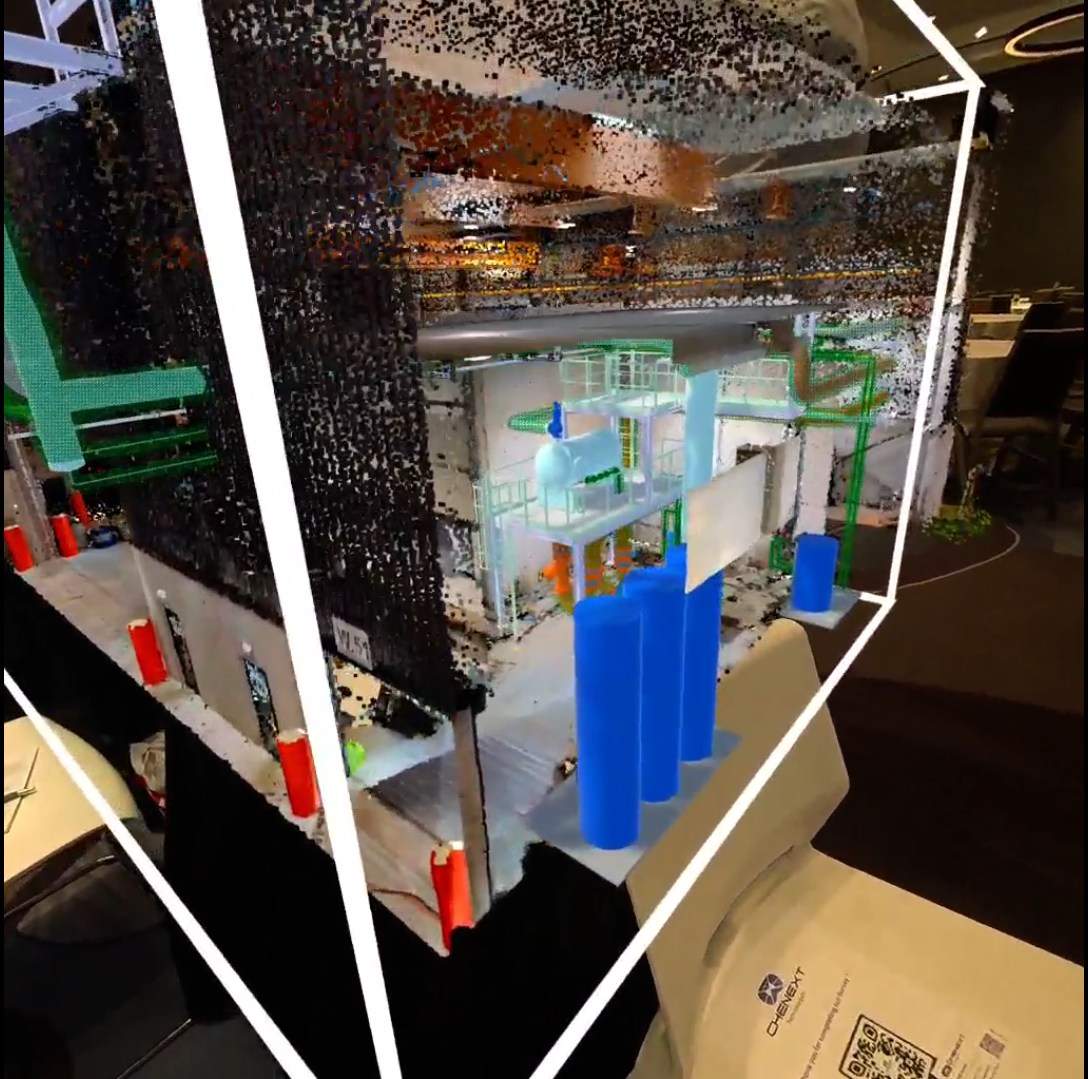

XR use case: Track the progress of your construction with AR

Problem: During construction of a new process plant, it often is: first come, first served. Contractors do not always come on-schedule and priority is given to who arrives first. This leads to potential deviations of the design and expensive clashes to be solved.

Solution: With our construction AR application you can track the progress of the work from today and tomorrow. Overlay your equipment with accurate positioning and on-site scheduling.

XR FOR EVERY PLANT LIFECYCLE STAGE

Commissioning

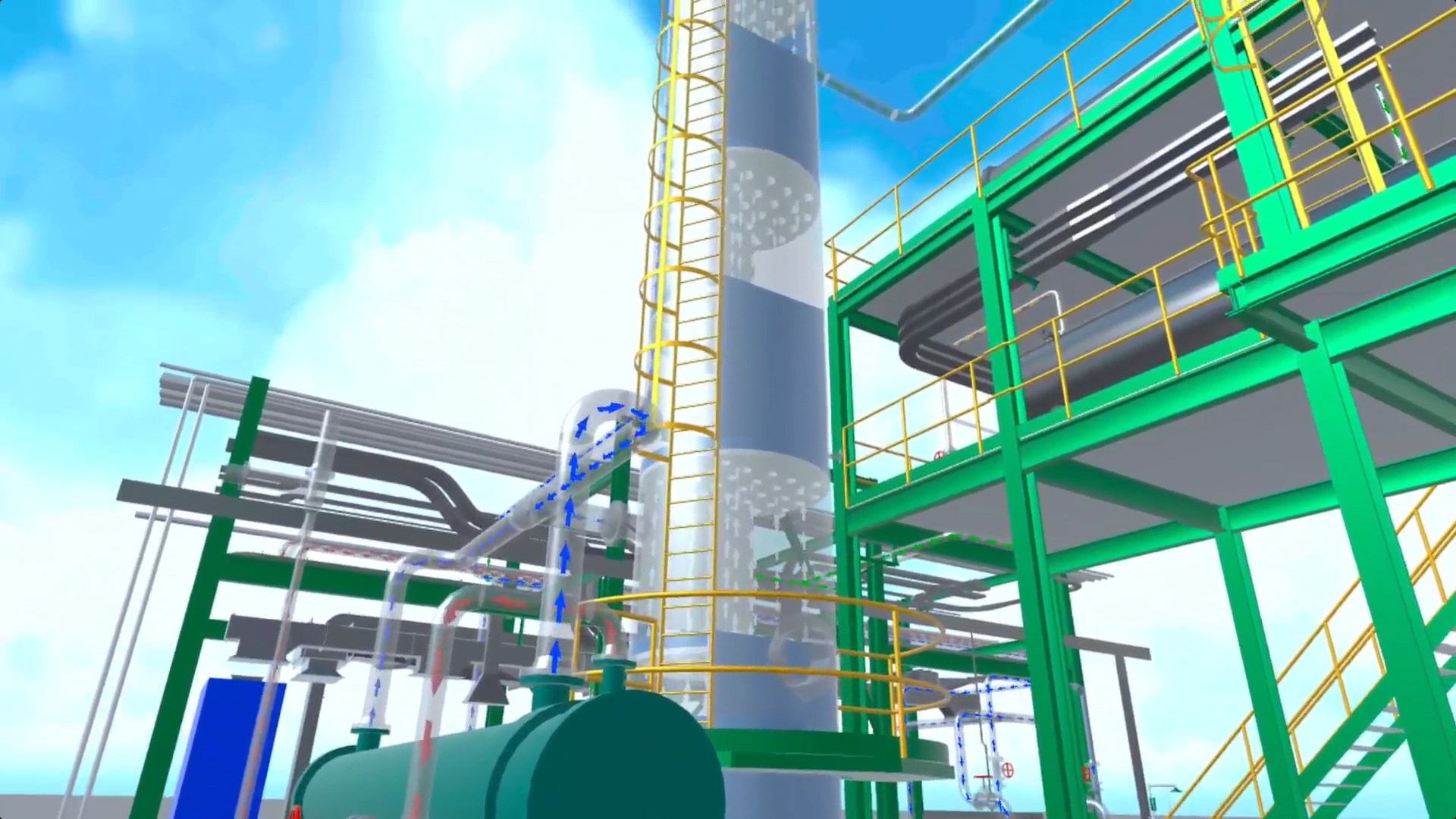

XR use case: Prepare the commissioning of your plant in advance using XR

Problem: Commissioning is a rigorous process to ensure a new installation complies with the design requirements and operates safely and reliably. This process can only be started once the installation is constructed and requires specialized experience. The system is continuously tested on-site, which can be time-consuming and can introduce high-risk operational challenges.

Solution: With our XR solutions, you can reuse your 3D design models for multiple purposes beyond design and construction. They can be used to train personnel, test business units and simulate processes remotely and even before the construction is completed. This virtual commissioning will cut the duration of the commissioning stage significantly, so that production can start earlier, leading to a substantial added revenue!

XR FOR EVERY PLANT LIFECYCLE STAGE

Operations

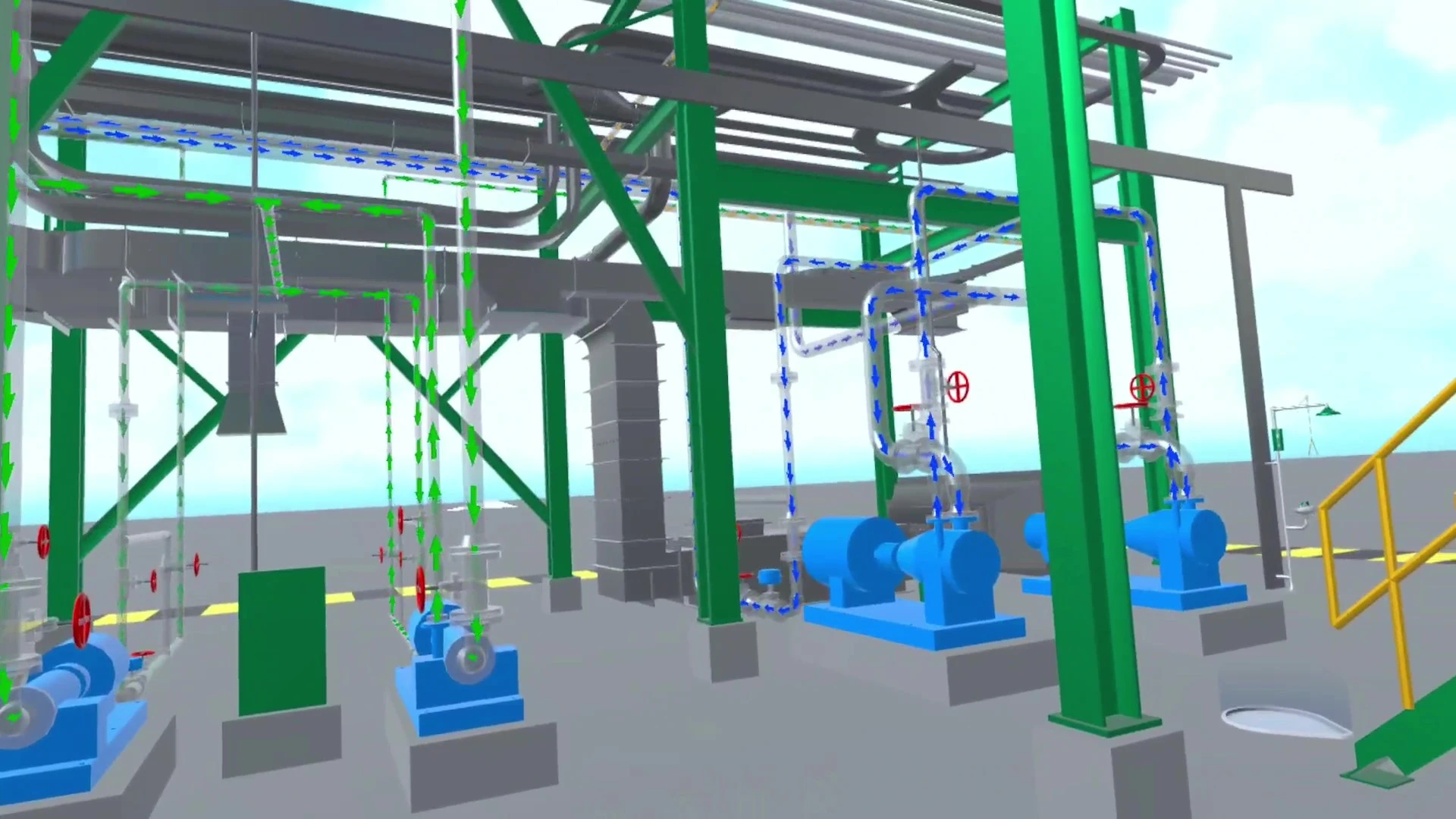

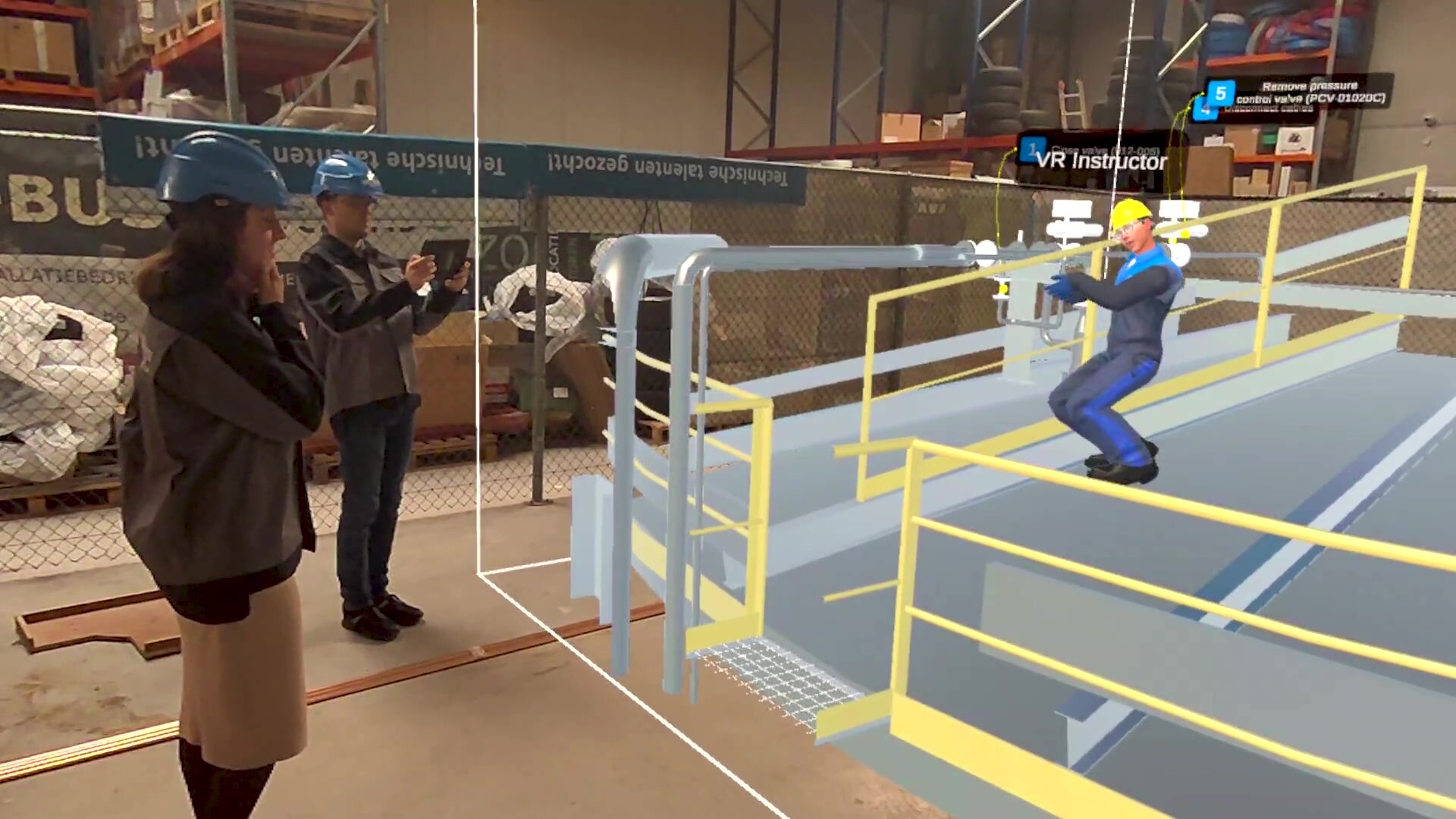

XR use case: Train and assist your operators with VR and AR

Problem: In every industry, a rapid generational shift is occurring: experienced workers are nearing retirement, while the incoming workforce tends to have less education and lower motivation to commit long-term roles, creating a gap in critical knowledge and expertise. As smaller teams take over operations, they struggle with increased workloads and a lack of hands-on training.

Solution: Our XR training applications enable faster onboarding by allowing new operators to practice complex tasks in an immersive, safe environment without real-world risks. It provides real-time assistance and hands-on simulations, ensuring operators gain confidence and proficiency through experiential learning. With continuous access to general and self-authored training, the application supports lifelong learning, helping smaller teams retain critical skills and adapt to evolving operational demands.

XR FOR EVERY PLANT LIFECYCLE STAGE

Inspection & Maintenance

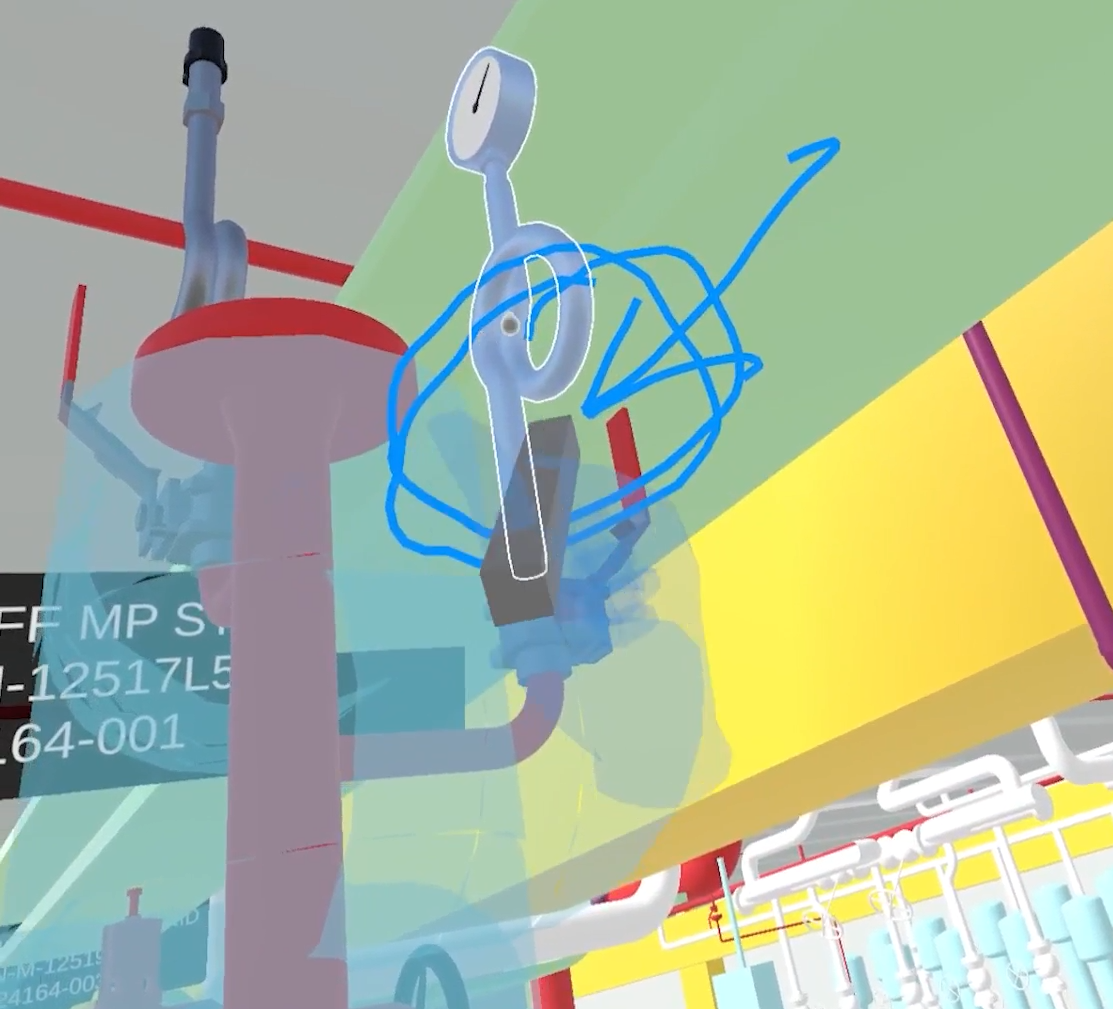

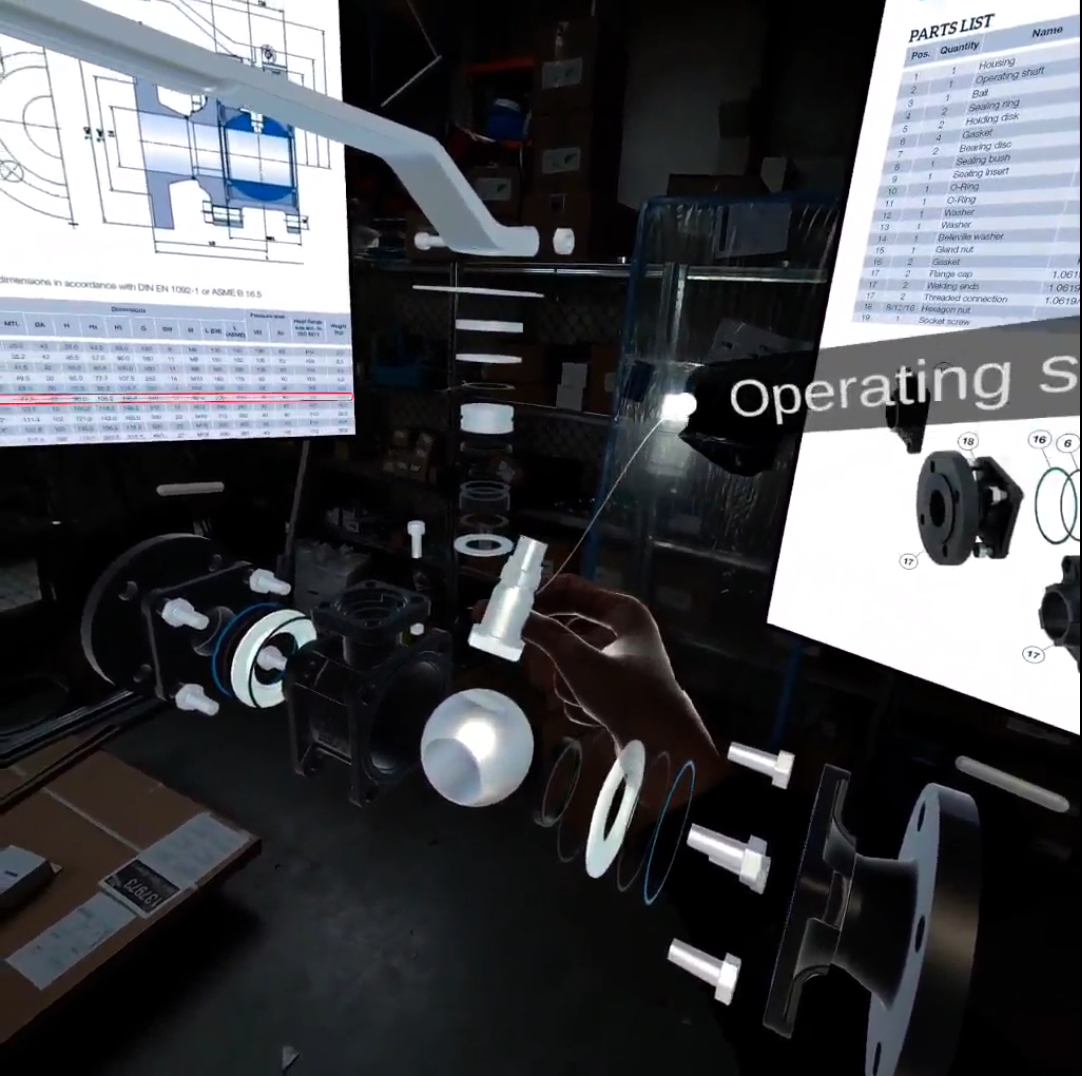

XR use case: Inspect and provide optimal maintenance with the help of accurate visual data

Problem: Inspection and maintenance in a process plant are often hindered by limited access to accurate documentation, making it difficult for technicians to diagnose and resolve issues efficiently. Unpredictable defects can arise, but a lack of real-time data and historical records slows down decision-making. Longer downtime increases safety risks and operational costs, while reducing the production revenue.

Solution: With our XR software modules, technicians are able to have real-time access to digital documentation at their fingertips for instant diagnostics. Step-by-step AR-guided installation allows technicians to perform maintenance procedures more accurately, reducing errors and rework. Our modules contain remote expert guidance to help technicians to collaborate and resolve issues real-time during maintenance enabling fast and precise feedback.

XR FOR EVERY PLANT LIFECYCLE STAGE

Decommissioning

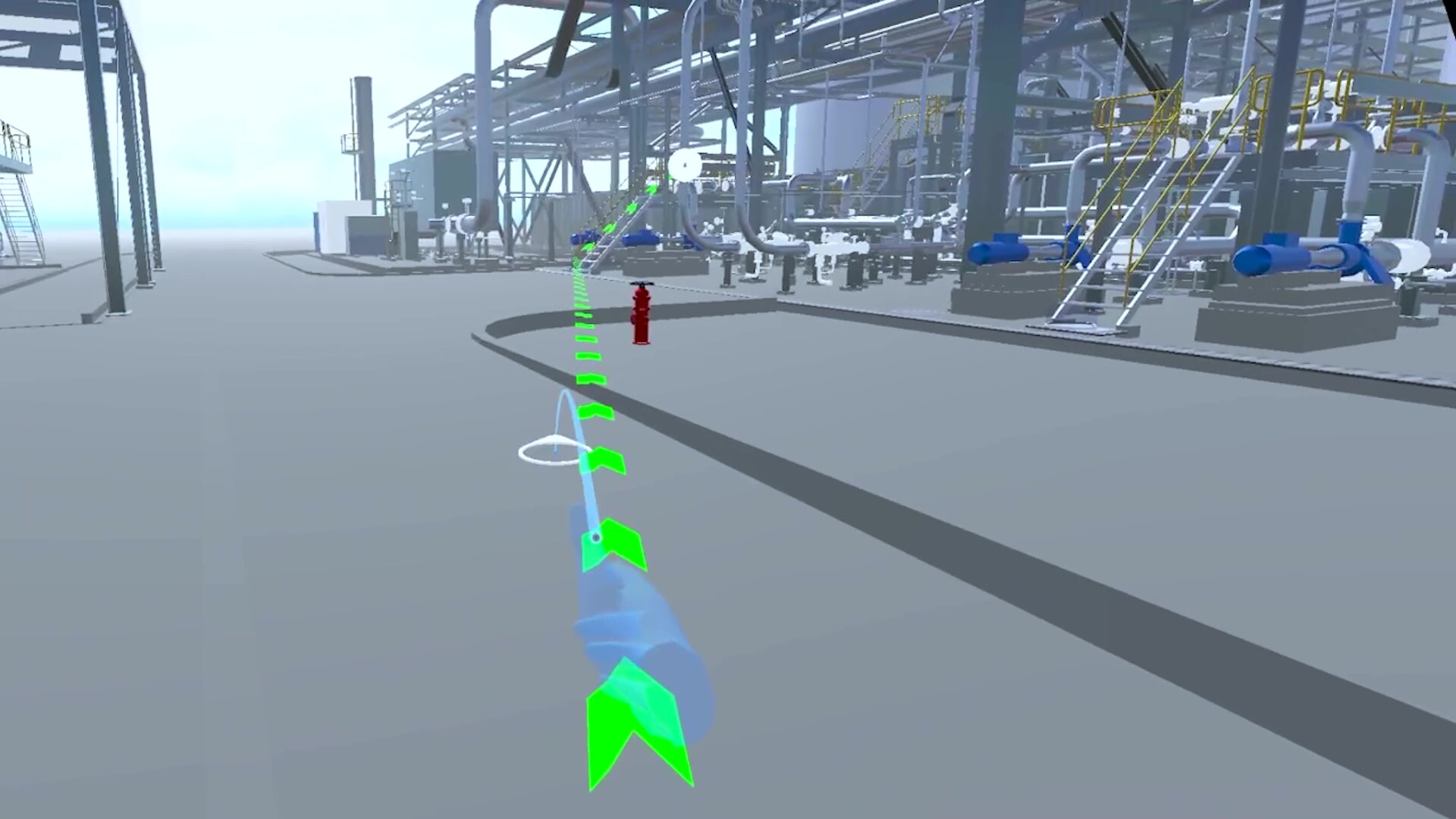

XR use case: Ensure safe shutdown and recovery of your assets with AR visual guidance

Problem: Decommissioning industrial facilities involves safely shutting down operations, dismantling equipment, and managing hazardous materials. Some equipment assets are recycled for other process plants. Since shutdowns are not practiced often, workers may lack the necessary experience to execute them efficiently, which can lead to unsafe demolitions practices and extended downtime.

Solution: Our VR, MR and AR software applications allow the decommissioning crew to simulate the dismantling procedures and optimize workflows to ensure safe and quick recovery. With using our AR visual guidance tool, experts are able to remotely assist and oversee operations as if they are present on-site.

XR FOR EVERYONE

Problem: Different departments within a company—such as HR, operations, sales, and engineering—require specific types of information tailored to their roles. However, this often leads to data silos, where critical information is stored in separate systems, making cross-departmental access difficult. As a result, employees struggle to retrieve the right data quickly, leading to inefficiencies and delays when making key decisions. Without a user-friendly and integrated system, accessing vital information when it is needed most becomes a major challenge.

Solution: Our XR software solutions are compatible for multiple devices, such as headsets, smartphones and tablets, providing an intuitive natural user interface that can be easily used anywhere and anytime, without the need of a powerful computer. Our solutions connect seamlessly with your database, allowing different departments to access a single source of truth filtered for your particular role. They go beyond just being a training module or visualization tool for engineers — HR can leverage it as an immersive recruitment tool for training and onboarding or sales teams can use it as an interactive aid to showcase products. Even executive leaders can use our XR applications for overseeing

XR FOR EVERY PARTNER

At CHENEXT Technologies, we strive to provide XR solutions to support the whole process industry. This means that our XR technology is not limited to process plant asset owners, but also benefits all their partners and suppliers. For component manufacturers we bring solutions to provide contextual information of their installed assets; for schools we provide virtual work environments to educate their students; for firefighters we bring a visually enhanced solution to train emergency scenarios. By establishing strong and strategic partnerships with all stakeholders of the process industry, we create a connected and collaborative industrial ecosystem that drives innovation, efficiency and safety.